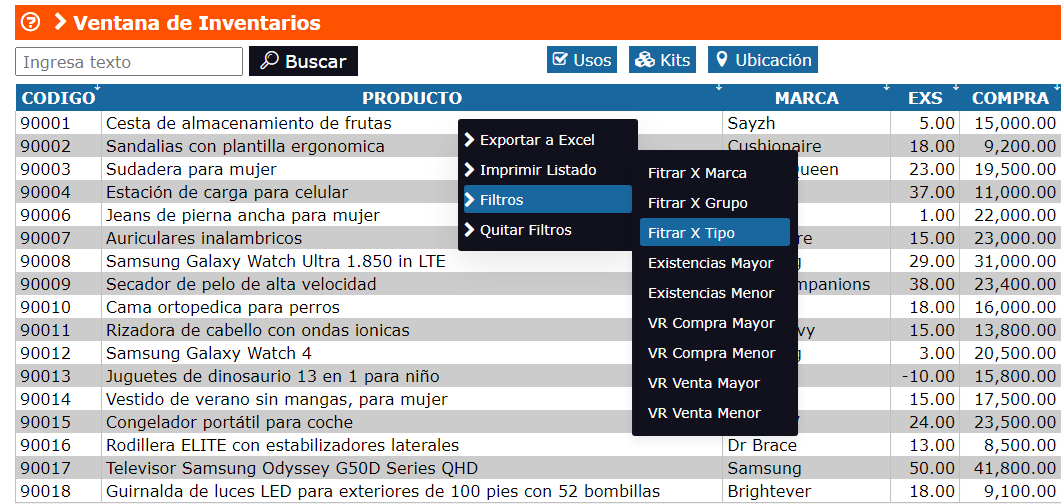

5 Examples: Neural Networks Benefit a Warehouse Inventory System

Technology is advancing rapidly and artificial neural networks, a key field of artificial intelligence (AI), have begun to transform the way companies manage their inventories. In an environment where efficiency and precision are crucial, neural networks can offer innovative solutions to optimize inventory management in warehouses. Below, we explore five ways in which neural networks can make a difference in this field.

1. Demand Forecasting

One of the main challenges in inventory management is accurately predicting the demand for products. Traditional systems rely on historical data and simple calculations, but neural networks have the ability to analyze complex patterns of data over time. By integrating factors such as market trends, seasonality, promotional campaigns, and changes in customer behavior, neural networks can make more accurate predictions about future demand. This reduces the possibility of overstock or stockouts, allowing for better planning and optimization of warehouse space.

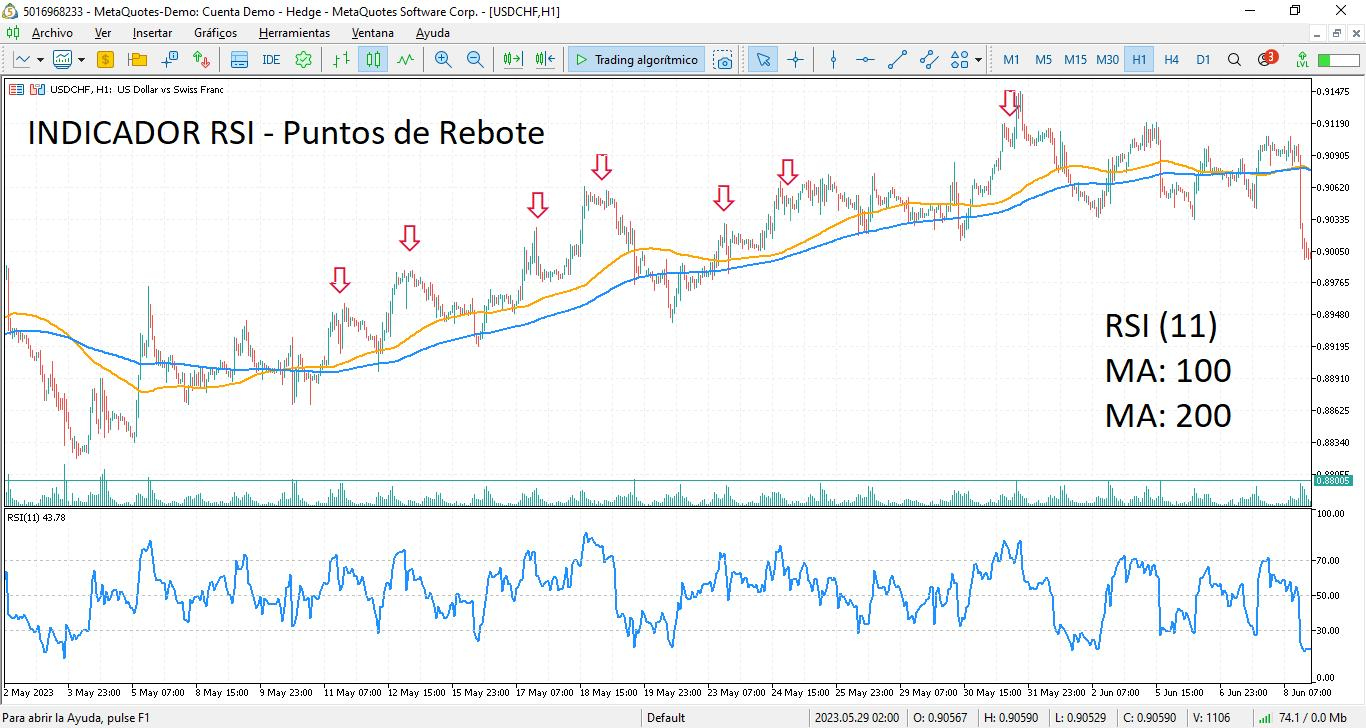

2. Optimization of Inventory Levels

An inventory system that uses neural networks can continuously learn what the optimal stock levels are for each product. Through the analysis of historical sales and replenishment data, it can dynamically adjust the quantities of products stored to ensure there is always enough without having an unnecessary excess. This approach can also take into account delivery times, price fluctuations, and supplier conditions, allowing for much more efficient management of warehouse resources.

3. Fraud and Anomaly Detection

Neural networks have an incredible ability to identify unusual patterns in large data sets. In an inventory system, this can translate into real-time detection of errors or fraud. For example, if there is a discrepancy between the physical stock and the one registered in the system, or if anomalous movements of merchandise are detected, a neural network can alert the warehouse manager to take preventive actions. This type of technology not only improves the accuracy of inventories but also reduces the risk of merchandise loss or fraudulent manipulation.

4. Optimization of Routes and Movements Within the Warehouse

An efficient warehouse not only depends on a well-managed inventory but also on the speed and accuracy with which products are handled. Neural networks can help optimize routes within the warehouse so that employees make the least number of movements possible when picking up or storing products. Based on real-time data about the location of products and their demand, these systems can guide operators through the fastest and most efficient routes, reducing wait times and increasing overall warehouse productivity.

5. Predictive Maintenance of Warehouse Equipment

In a warehouse, equipment malfunction can completely stop operations, resulting in loss of time and money. Neural networks applied to predictive maintenance can monitor the performance of equipment such as forklifts, conveyor belts, and picking robots, anticipating when a failure is likely to occur. By learning from historical data on equipment usage and wear, these systems can predict when maintenance should be performed before a breakdown occurs, avoiding unplanned interruptions in the logistics chain.

Neural networks represent an evolution in inventory management. By learning from real-time data and historical patterns, they offer customized and highly efficient solutions to anticipate demand, optimize space and resources, detect fraud, improve movements within the warehouse, and keep equipment running. Companies that implement this technology will be better equipped to face the challenges of an increasingly competitive market while reducing costs and improving their ability to respond to customer demand.

At Inventarios1A, we believe in the power of technology to transform inventory management, and neural networks are a clear example of how the future of storage is here today.