Kanban in batch production environments: Challenges and solutions.

Kardex in batch production manufacturing environments: Challenges and solutions

In the manufacturing industry, inventory management is crucial to maintaining efficiency and productivity. The Kardex system is a tool used to control and manage inventories in batch production manufacturing environments. However, implementing Kardex in these environments can present significant challenges. In this article, we will explore the challenges and solutions for implementing an effective Kardex system in batch production manufacturing environments.

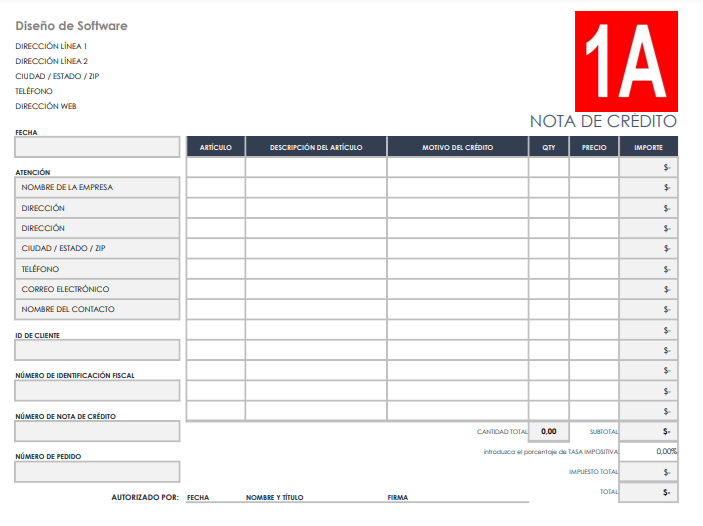

What is a Kardex system?

A Kardex system is an inventory control method that uses cards or records to track the quantity of items in stock. Each card or record corresponds to a specific item and is updated every time a transaction is made, such as a sale or purchase. The Kardex system allows companies to maintain an accurate record of their inventories and make informed decisions about inventory management.

Challenges in implementing Kardex in batch production manufacturing environments

Implementing a Kardex system in batch production manufacturing environments can present several challenges, including:

- Complexity of production processes: In batch production manufacturing, production processes can be complex and varied, making it difficult to implement a Kardex system that meets the specific needs of the company.

- Large number of items and variants: In batch production manufacturing, a large number of items and variants can be produced, making it difficult to maintain an accurate record of inventories.

- Fluctuations in demand: Demand for products can fluctuate significantly in batch production manufacturing, making it difficult to predict and manage inventories effectively.

- Limitations in technology and resources: Implementing a Kardex system can require significant investments in technology and resources, which can be a challenge for companies with budget constraints.

Solutions for implementing an effective Kardex system in batch production manufacturing environments

Despite the challenges, there are several solutions that can help implement an effective Kardex system in batch production manufacturing environments, including:

- Implementing an automated inventory management system: An automated inventory management system can help reduce errors and improve accuracy in inventory management.

- Using radio frequency identification (RFID) technology: RFID technology can help track and manage inventories more efficiently and accurately.

- Developing a customized inventory management plan: A customized inventory management plan can help adapt the Kardex system to the specific needs of the company.

- Training personnel in inventory management: Training personnel in inventory management can help ensure that the Kardex system is used effectively and efficiently.

Conclusion

Implementing a Kardex system in batch production manufacturing environments can present significant challenges, but there are several solutions that can help overcome them. By implementing an automated inventory management system, using RFID technology, developing a customized inventory management plan, and training personnel in inventory management, companies can ensure that their Kardex system is effective and efficient. With a well-implemented Kardex system, companies can improve inventory management, reduce costs, and increase productivity.