What is a Shrinkage or Reduction?

In inventory management, the term Shrinkage or Reduction refers to the decrease in the quantity of a product available in inventory due to various causes unrelated to the sale of the product. These shrinkages can have a significant impact on costs and operational efficiency, making it essential to understand and manage them properly.

Common Causes of Shrinkage or Reduction

Shrinkages can occur for a variety of reasons, and it's crucial to identify them to implement corrective measures. Some of the most common causes include:

- Waste in production: During the manufacturing process, some raw materials may not be used completely or may be damaged, resulting in a decrease in inventory.

- Losses due to handling: Products can be damaged during transportation, storage, or handling, leading to their unusability and, consequently, shrinkage.

- Expiration: Perishable products that are not sold within their shelf life become shrinkage.

- Theft: Inventory can decrease due to internal or external theft.

- Administrative errors: Inaccuracies in records, such as incorrect counts or data entry errors, can lead to discrepancies between physical and recorded inventory.

Common Examples of Products Prone to Shrinkage

Certain products are more susceptible to shrinkage due to their nature or storage conditions. Here are some examples and how to address them:

Fuel

- Problem: Fuel is prone to evaporation losses, and if not stored properly, these losses can be significant.

- Solution: Use high-quality storage tanks with temperature control systems and adequate seals to minimize evaporation. Implement rigorous fuel entry and exit records to detect potential losses.

Fruits and Vegetables

- Problem: Fresh products like produce have a limited shelf life. If purchased in excess or not managed properly, these products can spoil quickly.

- Solution: Make purchases based on actual demand and use inventory rotation methods to ensure older products are sold first. Store products in suitable temperature and humidity conditions to prolong freshness.

Seasonal Products

- Problem: Items like fashion clothing or seasonal products lose value out of season.

- Solution: Plan purchases and inventory of seasonal products to coincide with demand peaks. Consider liquidation strategies before the end of the season to minimize financial shrinkage.

Products with Expiration Dates and No Returns

Problem: Some products with expiration dates cannot be returned or exchanged by the supplier, resulting in shrinkage if not sold on time.

Solution: Continuously monitor products with approaching expiration dates and implement promotions or discounts to accelerate sales before they expire. Negotiate with suppliers to obtain more favorable terms on perishable products, such as the possibility of returns or exchanges.

Types of Shrinkage

There are several types of shrinkage that can affect a company's inventory. These are some of the most relevant:

- Technical shrinkage: Refers to losses that occur during the production process due to the nature of the product or the process itself. For example, in the food industry, a certain amount of raw material may be lost during cooking or processing.

- Shrinkage due to expiration: Occurs when products have a limited shelf life and are not sold on time.

- Shrinkage due to handling: Includes damage suffered during product handling in warehouses, during transportation, or at the point of sale.

Impact of Shrinkage on the Company

If not managed properly, shrinkage can represent a significant cost for companies. In addition to the direct loss of product, shrinkage can affect profit margins, inventory record accuracy, and the ability to meet customer demand.

It is crucial that companies implement effective systems to identify, record, and reduce shrinkage. This will not only help minimize losses but also improve efficiency and profitability.

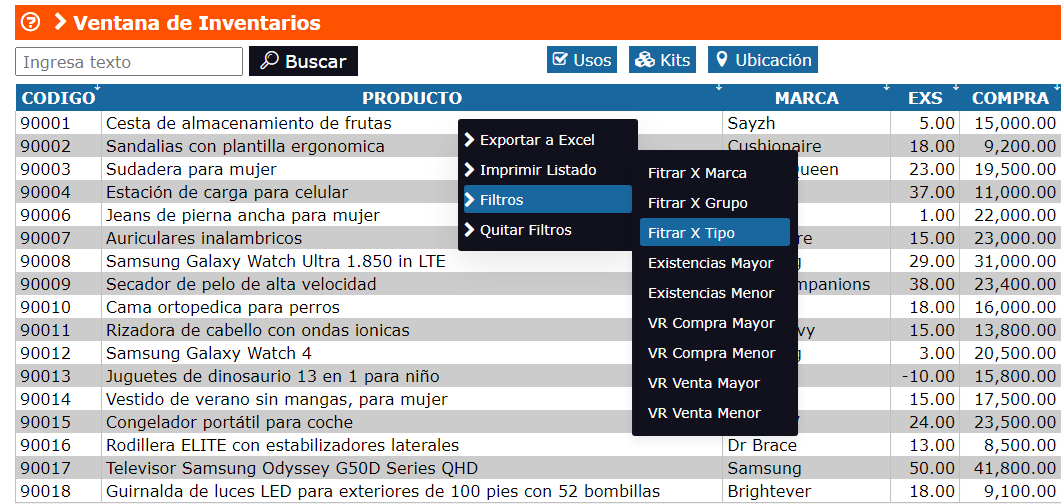

Managing Shrinkage with Inventarios1A

Inventarios1A provides advanced tools to manage shrinkage efficiently, helping companies maintain precise control over their inventory.

- Detailed shrinkage recording: Allows for clear recording of shrinkage, specifying the cause and type of reduction.

- Real-time monitoring: Offers visibility into shrinkage as it occurs, enabling managers to take corrective action immediately.

- Customized reports: Generates reports that help analyze the causes and frequencies of shrinkage, facilitating decision-making to reduce them.

- Inventory control: Improves the accuracy of inventory records, ensuring that shrinkage is reflected correctly in inventory balances.

Shrinkage or Reduction is a common phenomenon in inventory management, but its negative impact can be minimized with proper management. Understanding the causes, types, and consequences of shrinkage enables companies to implement effective strategies to reduce them. With Inventarios1A, you can manage and monitor shrinkage efficiently, ensuring that your business maintains rigorous control over its inventory and minimizes losses.