Production Orders

Production Order Management in Our Company

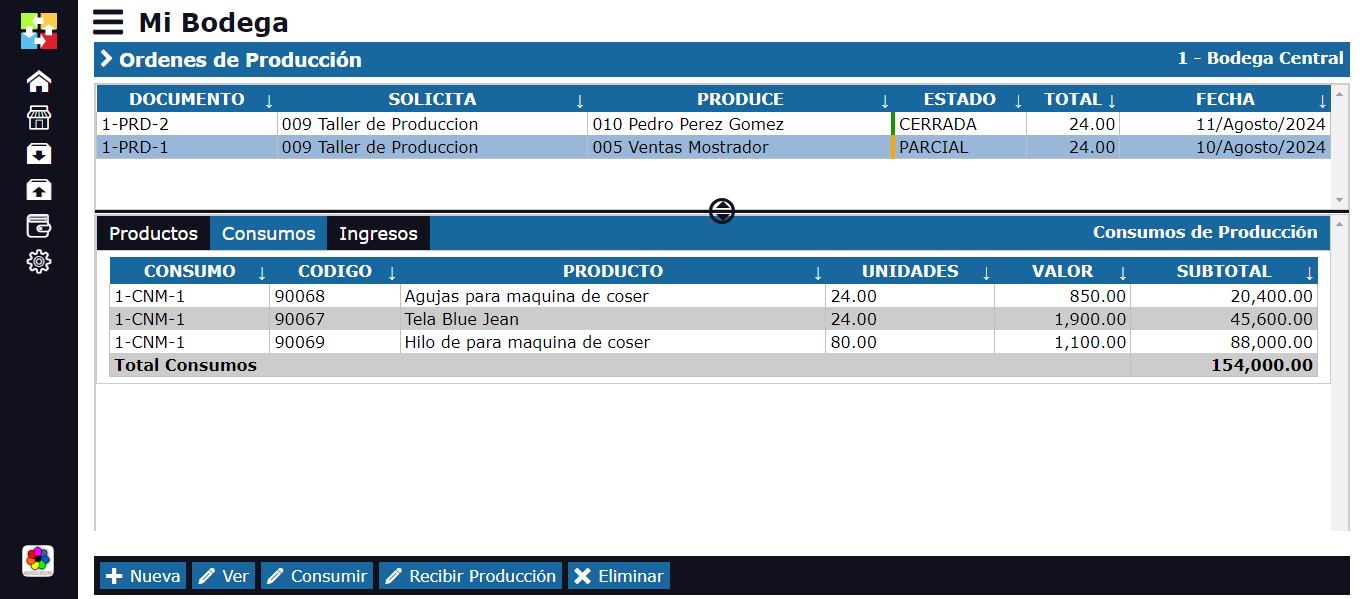

When our company manufactures products from raw materials, we use Production Orders, which are usually requests sent to the manufacturing department.

The Production Orders window has 3 tabs at the bottom.

- Products. These are the items we have to produce

- Consumptions: These are all the products that have been used to make the required product

- Incomes: As the product is manufactured, it is entered into the warehouse.

Practical Example:

- The warehouseman checks the stock and detects that the inventory of Plastic Chairs with two arms is below the minimum stock.

- The warehouseman can (optionally) generate a purchase order to cover this need.

- The Production Manager reviews the order (optionally).

- The Production Manager issues a Production Order to manufacture a certain amount of Plastic Chairs with two arms.

- The Production Order is approved and ready to be processed in the factory.

IMPORTANT:

The product to be manufactured MUST be classified in the inventory as a Product of the Type: PRODUCTION.

The product must be correctly configured, which means that its subcomponents or raw materials must have been previously defined in the inventory (Product KIT Configuration).

Once the Production Order has been issued, it is possible to make Warehouse Exits directed to that Production Order.

Finally, record the products in the inventory as they are manufactured.