Inventory optimization for made-to-order production companies.

Inventory optimization for made-to-order production companies

Made-to-order production, also known as "made-to-order", is a business model in which companies produce products only when they receive a specific order from a customer. This approach can be beneficial for companies that want to reduce storage costs and minimize the risk of obsolete inventory. However, it also presents challenges in terms of inventory management. In this article, we will explore strategies for optimizing inventory in made-to-order production companies.

Challenges of made-to-order production

Made-to-order production can be a challenge for companies that do not have an efficient inventory management system. Some of the most common challenges include:

- Delays in delivery: Made-to-order production can lead to delays in delivery, as the company must produce the product after receiving the order.

- Variable production costs: Production costs can vary depending on the quantity and type of product being produced.

- Material and component management: The company must manage the materials and components needed to produce the product, which can be a challenge if there is no efficient inventory management system.

Strategies for optimizing inventory in made-to-order production

Here are some strategies that companies can implement to optimize inventory in made-to-order production:

1. Demand analysis

It is essential to analyze the demand for products to determine the quantity and type of product that should be produced. This can help reduce production costs and minimize the risk of obsolete inventory.

2. Material and component management

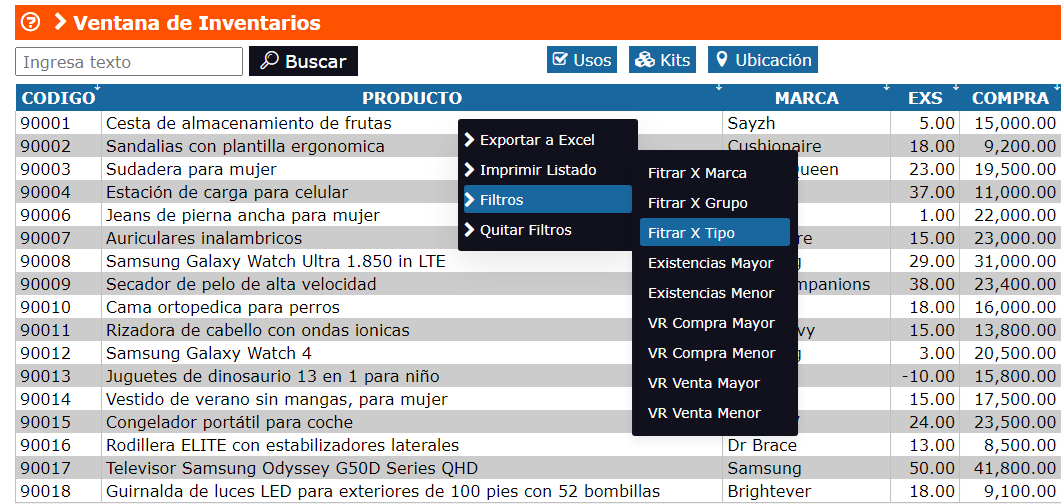

The company must manage the materials and components needed to produce the product efficiently. This can include implementing an inventory management system that allows tracking of materials and components in real-time.

3. Batch production

Batch production can be an effective strategy for reducing production costs and minimizing the risk of obsolete inventory. The company can produce batches of products that can be customized according to the needs of customers.

4. Collaboration with suppliers

Collaboration with suppliers can be essential for optimizing inventory in made-to-order production. The company can work with suppliers to ensure that materials and components are available on time.

5. Implementation of information technologies

The implementation of information technologies, such as inventory management systems and enterprise resource planning (ERP) software, can help optimize inventory in made-to-order production. These technologies can provide real-time information on the availability of materials and components, which can help reduce production costs and minimize the risk of obsolete inventory.

Conclusion

Made-to-order production can be a challenge for companies that do not have an efficient inventory management system. However, by implementing strategies such as demand analysis, material and component management, batch production, collaboration with suppliers, and the implementation of information technologies, companies can optimize inventory and reduce production costs. It is essential that made-to-order production companies implement an efficient inventory management system to ensure they can meet customer needs efficiently and effectively.