Warehouse Management: Keys to Efficiency and Organization

Proper warehouse management is crucial for the success of any business that handles large volumes of inventory. A well-planned warehouse not only optimizes space but also improves speed and accuracy in daily operations. In this article, we will discuss some of the most important aspects related to warehouse location and internal merchandise organization.

How to Choose a Warehouse Location?

Choosing a warehouse location is a strategic decision that can directly affect the efficiency of the supply chain and operational costs. To select the best location, it is essential to consider several factors:

Proximity to markets: The warehouse should be close enough to the main markets or customers to reduce transportation costs and delivery times. This is especially important for companies that handle perishable products or with high demand.

Accessibility: The warehouse should be located near main roads, highways, or ports if the business depends on importing or exporting goods. Accessibility to suppliers is also important.

Land and construction costs: Urban areas usually have higher costs, so many companies opt for suburban or rural locations that offer a balance between cost and accessibility.

Available services: Nearby infrastructure, such as access to public services (electricity, water, internet) and labor availability, also influences the decision.

Where Should Warehouses Be Located?

In general, warehouses should be located in strategic points that allow a continuous flow of goods between suppliers and customers. Companies that operate at the national or international level often choose areas near logistics centers, industrial zones, or free trade areas to maximize efficiency.

For local businesses, a warehouse located near the base of operations or the main customers can significantly reduce transportation times and associated costs. Additionally, warehouses in areas further away from cities can be more economical, as long as the additional logistics costs are not prohibitive.

What is the Warehouse Area?

The warehouse area is the physical space within the warehouse where products are stored, handled, and managed. This space should be organized efficiently to optimize workflow and use of available space. Depending on the type of products and operations, the warehouse area can be divided into several specific zones, such as:

- Reception area

- Storage area

- Order preparation area

- Dispatch area

The organization of the warehouse area depends on the size of the facility, the nature of the stored products, and the volume of daily operations.

What is Product Placement?

The product placement in a warehouse refers to the physical arrangement of items within the storage area. This organization is key to ensuring that products are easy to locate, which reduces order preparation time and avoids errors.

There are several methods for organizing products in a warehouse, such as:

Fixed location: Each product has a designated place within the warehouse. It is a simple method, but it may not be efficient in terms of space when there are products with low turnover.

Dynamic location: Products are placed in any available space. It is more efficient in terms of space, but it requires an advanced inventory management system to quickly locate items.

Product placement should be planned based on the type of inventory, the frequency of movements, and the size of the products.

Where Should a Warehouse Be Situated?

A warehouse should be situated in a location that optimizes the company's logistics, such as in areas near production or distribution centers. For a smooth supply chain, it is ideal that warehouses are located near key infrastructure such as ports, airports, or land transportation networks. This facilitates the movement of goods to and from the warehouse, reducing waiting times and transportation costs.

In the case of local businesses, a warehouse located near customers allows for faster delivery times and lower distribution costs. However, in companies with multiple sales or distribution points, it may be necessary to establish a network of warehouses to cover larger geographical areas.

What Are the Criteria for Product Placement in the Warehouse?

The criteria for placing products within the warehouse depend on the type of products and operational needs. Some of the most important factors to consider include:

Inventory turnover: Products that move faster (high turnover) should be located near dispatch areas or easily accessible. This reduces search times and order preparation times.

Dimensions and weight: Heavy or bulky products should be stored on easily accessible shelves and in low positions to avoid accidents and facilitate handling.

Special storage conditions: Some products require specific conditions, such as controlled temperature or low humidity. These items should be stored in appropriate areas within the warehouse to ensure their integrity.

Organization by categories: Storing products of similar categories in the same area can speed up item searches and improve efficiency in inventory management.

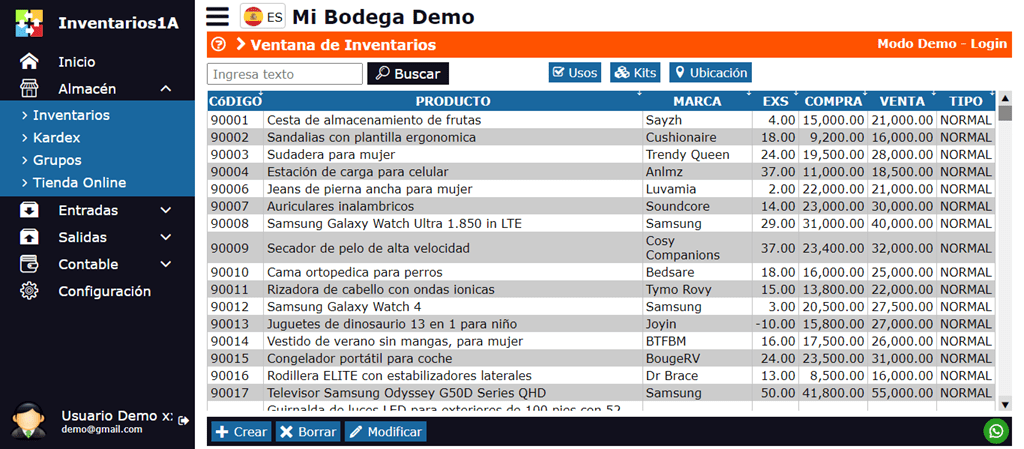

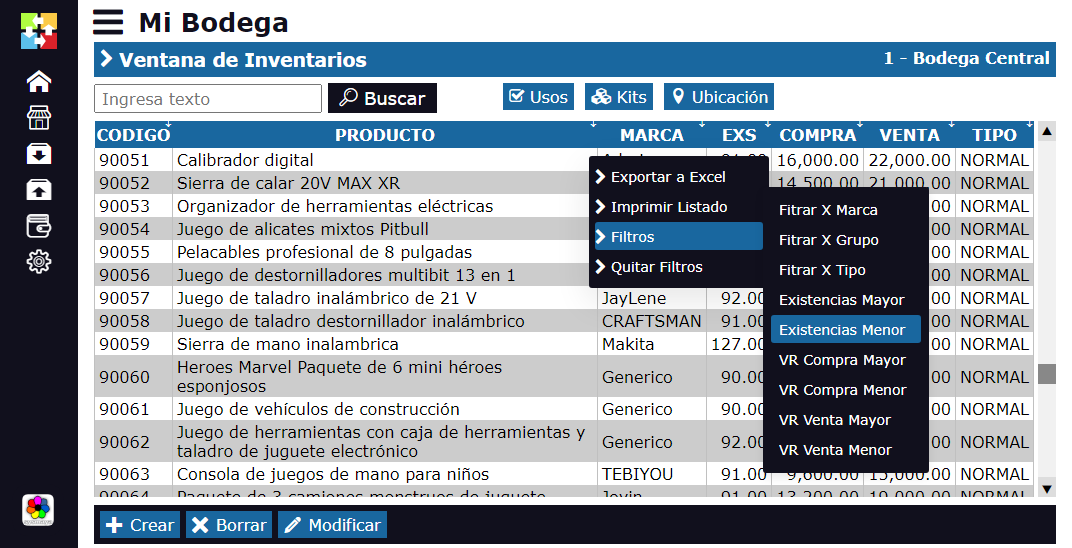

Efficient warehouse management depends largely on the warehouse location and internal product organization. Considering factors such as proximity to markets, accessibility, and inventory turnover is key to optimizing operations and ensuring that products reach their final destination quickly and efficiently. Implementing an inventory management system like Inventarios1A will not only allow you to keep an exact control of stock but also improve the organization and distribution of products within the warehouse.